- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Tantalum Carbide Coating Produsen, Supplier, Pabrik

Semikonduktor VeTek minangka produsen utama bahan Tantalum Carbide Coating kanggo industri semikonduktor. Penawaran produk utama kalebu bagean lapisan karbida tantalum CVD, bagean lapisan TaC sing disinter kanggo pertumbuhan kristal SiC utawa proses epitaksi semikonduktor. Lulus ISO9001, VeTek Semiconductor nduweni kontrol kualitas sing apik. VeTek Semiconductor darmabakti kanggo dadi inovator ing industri Tantalum Carbide Coating liwat riset lan pangembangan teknologi iteratif.

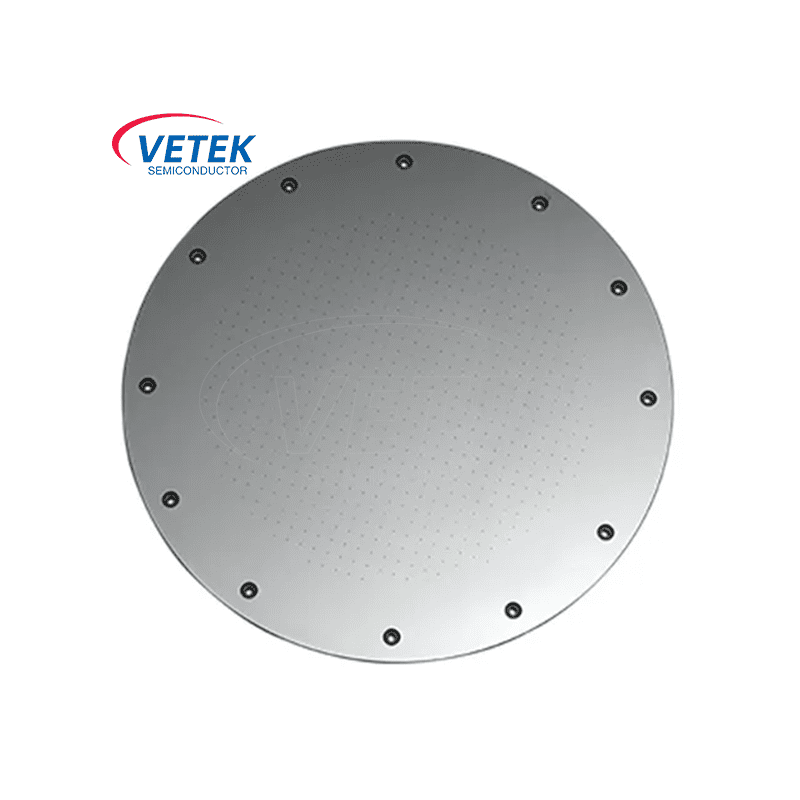

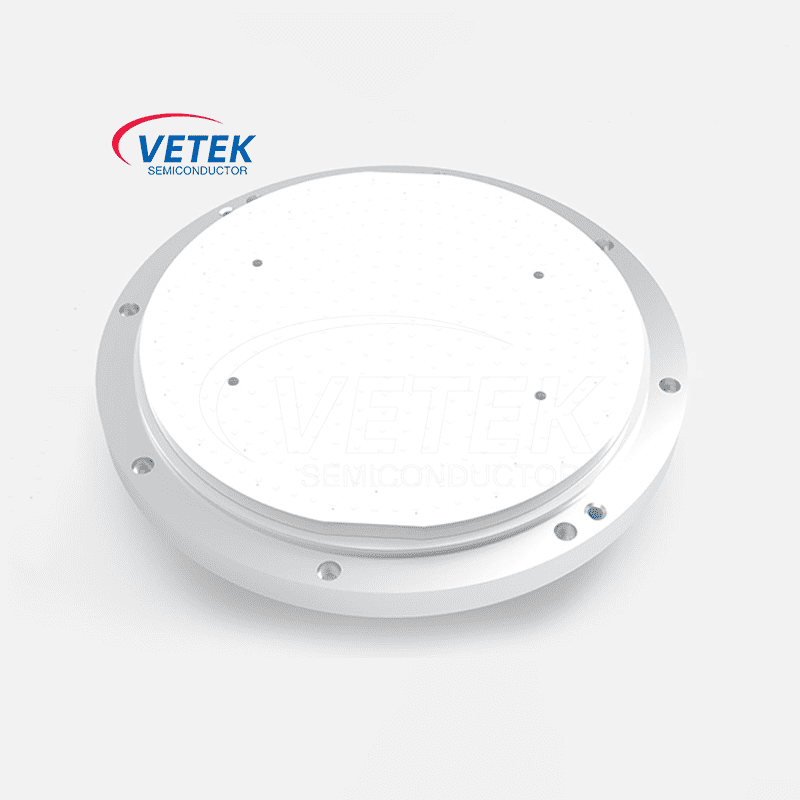

Produk utama yaikuTantalum Carbide coating defector ring, TaC coated diversion ring, TaC coated halfmoon parts, Tantalum Carbide Coated Planetary Rotation Disk (Aixtron G10), TaC Coated Crucible; TaC Coated Rings; TaC Coated Porous Graphite; Tantalum Carbide Coating Graphite Susceptor; TaC Coated Guide Ring; TaC Tantalum Carbide Coated Plate; TaC Coated Wafer Susceptor; TaC Coating Ring; TaC Coating Graphite Cover; TaC Coated Chunketc., kemurnian ngisor 5ppm, bisa ketemu syarat customer.

Grafit lapisan TaC digawe kanthi nutupi permukaan substrat grafit kanthi kemurnian dhuwur kanthi lapisan tantalum karbida kanthi proses Deposisi Uap Kimia (CVD) proprietary. Kauntungan ditampilake ing gambar ing ngisor iki:

Lapisan tantalum carbide (TaC) wis entuk perhatian amarga titik leleh sing dhuwur nganti 3880 ° C, kekuatan mekanik sing apik, kekerasan, lan tahan kanggo kejut termal, dadi alternatif sing apik kanggo proses epitaksi semikonduktor senyawa kanthi syarat suhu sing luwih dhuwur, kayata sistem Aixtron MOCVD lan proses epitaksi LPE SiC. Uga nduweni aplikasi sing akeh ing proses pertumbuhan kristal SiC metode PVT.

Fitur Utama:

●Stabilitas suhu

●kemurnian Ultra dhuwur

●Resistance kanggo H2, NH3, SiH4, Si

●Resistance kanggo stock termal

●Adhesion kuwat kanggo grafit

●Jangkoan lapisan conformal

● Ukuran nganti diameter 750 mm (Produsen mung ing China tekan ukuran iki)

Aplikasi:

● Susceptor pemanasan induktif

● unsur panas resistif

● tameng panas

Lapisan tantalum karbida (TaC) ing bagean silang mikroskopis:

Parameter VeTek Semiconductor Tantalum Carbide Coating:

| Sifat fisik lapisan TaC | |

| Kapadhetan | 14,3 (g/cm³) |

| Emisivitas spesifik | 0.3 |

| Koefisien ekspansi termal | 6.3 10-6/K |

| Kekerasan (HK) | 2000 HK |

| Resistance | 1×10-5Om *cm |

| Stabilitas termal | <2500 ℃ |

| owah-owahan ukuran grafit | -10~-20um |

| Ketebalan lapisan | Nilai khas ≥20um (35um±10um) |

TaC coating data EDX:

Data struktur kristal lapisan TaC:

| unsur | Atom persen | |||

| Pt. 1 | Pt. 2 | Pt. 3 | Rata-rata | |

| C K | 52.10 | 57.41 | 52.37 | 53.96 |

| M | 47.90 | 42.59 | 47.63 | 46.04 |

- View as